- Shaft sealing is done by a Mechanical Seal.

- The connections are provided in such a way that samples can be taken on line, without breaking the vacuum or interrupting the manufacturing.

- Thermocouple provided for the product temp. in the circulation line from the Homogenizer plus a Cone provided for last minute additions if any without breaking the vacuum.

- Finished products can be transferred to the storage Tank – Lobe pump not required.

- All contact parts in S.S. 316 and non-contact in S.S. 304.

- Hydraulic Power Pack : Is provided complete with a tank for oil, pump with Sol. Valves & Flow control valves with Motor.

- AVAILABLE CAPACITIES : 1000-5000 litres/hour.

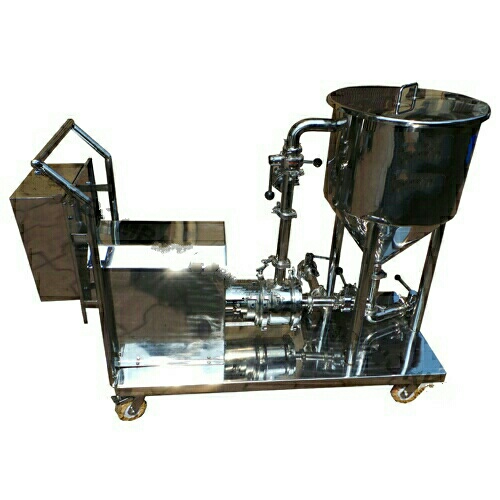

INLINE HOMOGENISER

INLINE HOMOGENISER

About INLINE HOMOGENISER machine

Uses and features of inline homogenisers

Homogenizing is a process of combining various substances to obtain a mixture of uniform consistency (homogeneous). A homogenizer is equipment used to break down the solid particles in a solution into very fine sizes to achieve a homogeneous solution. It consists of a blade mounted on a motor shaft rotating at high speeds. Depending on the applications (stirring/homogenization/mixing), we provide various types of blades to serve the required purpose. we offer inline homogenisers

We offer three variants of homogenizers based on the position of mounting, namely, Bottom entry homogenizer, Top entry homogenizer and Inline Homogenisers

| MODEL | SPEED (RPM) | CAPACITY (L) | POWER (KW) | |

| BEW-50 | 1400 & 2800 As Per Requirement |

050 | 1.5 | |

| BEW-100 | 50-100 | 2.2 | ||

| BEW-300 | 100-300 | 4 | ||

| BEW-800 | 200-800 | 7.5 | ||

| BEW-1000 | 300-1000 | 11 | ||

| BEW-1500 | 500-1500 | 18.5 | ||

| BEW-1500 | 800-2000 | 22 | ||

| BEW-3000 | 1000-3000 | 30 | ||

| BEW-5000 | 1500-5000 |